Blockchain In Supply Chains

Blockchain, the distributed-ledger technology that sits at the heart of cryptocurrencies, has the potential for multiple applications in business, especially supply chains.

To date, however, there has been more talk and hype about blockchain than implementation at scale, despite the many pilots underway. There are good reasons for this. For one, the technology is new and not yet mature. Two, to be effective in business, blockchain requires open, inclusive systems and data sharing between multiple players, which is antithetical to most businesses. Finally, there is no “one size fits all” approach to applying blockchain, as the use case varies by industry and company, and the actual problem being addressed.

In an increasingly digitized environment, with all kinds of devices picking up data, blockchain has a stellar virtue: It is essentially a secure database that makes it almost impossible to manipulate data. But what is needed to make blockchain useful in a supply chain—at scale?

Choosing a Use Case

The first hurdle is identifying a problem you want to solve. There are good use cases for blockchain, but for every good use case there are 10 bad ones. You can track shipments of tomatoes with blockchain, but why bother? For tomatoes and most items, a standard database will do the job just fine.

Tracking shipments of meat or fish makes more sense, as retailers and consumers have an interest in knowing the provenance of these products, and how they were shipped, in terms of duration, temperature, humidity, and storage. Tracking drug shipments is also a good use case, as hospitals and pharmacies must be sure they are receiving non-counterfeit goods—and biopharma firms want to know that returns from hospitals are authentic.

Applying blockchain to supply-chain data tracking is as much an organizational challenge as a technology challenge.

Success Factors

Once a good use case is identified, there are four requisite elements necessary for success: 1) data is digitized, easily collected, and shared regularly; 2) automation, enabled by smart contracts or invoices, is beneficial; 3) parties trust each other, which facilitates buy-in; and 4) benefits outweigh the effort.

Applying blockchain to supply-chain data tracking is as much an organizational challenge as a technology challenge. A robust IT infrastructure, powered by engineers willing to tackle a new project with a steep learning curve, is, of course, necessary. But, the extent to which blockchain is part of an overall digitization strategy, and the extent to which the firm is agile, and open to innovation and process change, will tip the benefits/effort ratio in your favor.

Getting Started

Then there’s the question of getting started. Who goes first? How do you engage other players in the chain? Who leads the framework development—and takes the responsibility of defining standards? Being the first mover is certainly a challenging task—bringing the right partners together, taking responsibility for a new system, and doing so without a guaranteed return-on-investment.

On the first point, you start with a small, internal blockchain project, without partners. Once comfortable, you can extend it to adjacent partners in the chain. But that might not suffice to complete the project unless you have the clout to engage all players in the chain.

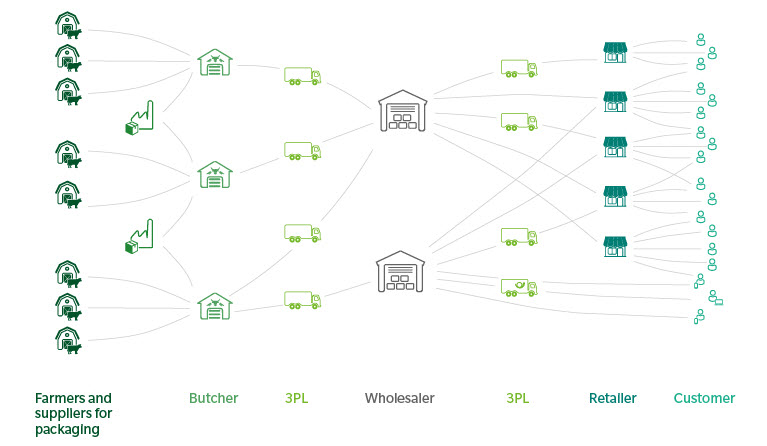

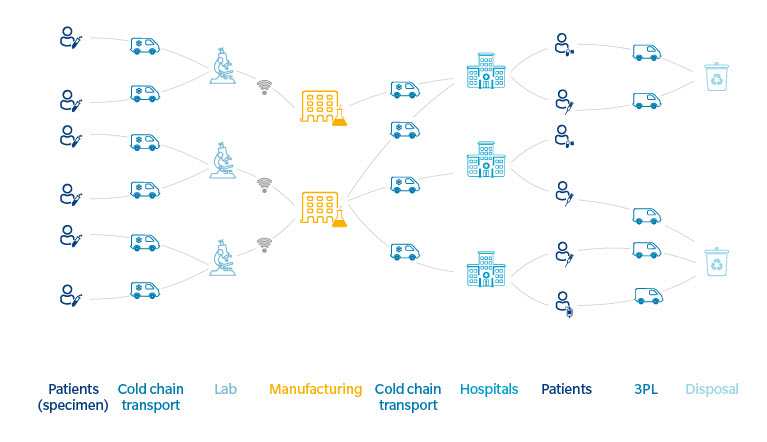

Consider the two chains mentioned above, meat and drug shipments. Logistics providers are engaged at the front- and back-end in the meat chain, and the beginning, middle, and end in the biopharma chain (see Retail Supply Network and Biopharma Supply Network). Logistics providers are the “glue” that holds these chains together, even though they are a step removed from the meat and biopharma businesses. But taking a leadership role would position logistics providers as innovation leaders, not followers, and protect them against disintermediation by new technologies. At the very least, logistics providers should ally with the largest player in the chain.

The meat and drug supply chains are very different—both in the type of data collected and the devices used to do so. Yet the end results are quite similar: The players who want access to reliable data will get it, and their overall systems will be increasingly digitized and streamlined. Blockchain not only allows players to capture much more data, but it also helps to make good use of it, which will support business practices, product development, and consumer engagement.

Whatever player takes the lead, all players stand to benefit. As the backbone for digitized supply chains, blockchain can be the impetus to collect more data, which can simplify auditing, accounting, and planning. The key to realizing the full potential of blockchain in the supply chain is to understand that implementation is not a pure technology project. It is equally a function of culture, strategy, innovation, and process change—as long as you apply it to a valuable use case